Passivhaus RDSAP EPC - 105A

An Interesting Challenge

In the middle of 2025 I was approached by a client seeking an RDSAP EPC assessment on a 10 year old property built almost entirely to Passivhaus standards.

At the time of construction in 2015, a SAP EPC had been produced to fulfill Building Control requirements, and with a lifespan of 10 years that EPC was just about to expire.

The property owner was looking to market the property and would therefore require a new EPC to do so legally, and he was looking to get the best outcome in terms of EPC rating.

This was a significant property with much bettter thermal performance than the minimums required by building control at the time and notably because of the design of the building, only minimal lengths of its external wall were straight.

To provide the best outcome in terms of accurate assessment and EPC rating for this property it was evident some areas needed particular consideration before visiting site. These were:

- The significant size and scale of the property.

- How to measure basic geometry of a property where only minimal lengths of external wall were 'geometrical'.

- Overiding u-values to get the most accurate EPC rating and provide justice to the building.

- Checking installed systems to make sure they were available in the PCDB such as heating and ventilation

- Consideration was also given to air-pressure testing

I was interested, but I was worried about being able to provide the best outcome.

The owner however had been heavily involved in the initial construction of the property and continued to maintain successful relationships with all parties involved, so extensive documentary evidence was available, and further evidence could be sought if necessary.

The owner convinced me it would be possible somehow and it would work out fine.

Size and Scale

Although I was initially concerned about the size of the property, this in the end was a minor consideration.

We would simply apply the same rules and approach that would be employed for any other assessment and it should simply work out well.

The floor design was consistent across the whole of the floor area, the roof design was too, and there were two distinct wall types.

This lead to a 'standard' breakdown and modelling of the property.

Basic Geometric Measurements

There are some basic geometric measurements that energy assessors take when conducting an EPC assessment on an existing property.

These apply to each floor of the building plus any ‘extensions’ which may be real extensions, or virtual ones - where a property is split into different parts having differing ceiling heights or floor types or roof types etc.

In particular the measurements include:

- Floor area

- Lengths of external wall (known as the Heat Loss Perimeter)

- Lengths of any party wall

- Ceiling height

For a ‘standard’ rectangular house this is straightforward, an assessor uses a laser measure and multiplies the length and width together to arrive at the floor area.

Also, measuring lengths of external wall is straightforward and multiple lengths of party wall or multiple lengths of HLP wall can be easily summed to arrive at the required figures.

Ceiling heights are also easy to measure with a laser measure.

In the case of our 'Passivhaus' property we had a challenge because none of the walls were straight and a different approach would be required to calculate the floor area and lengths of external wall.

I didn't have a solution for this at the time and I was concerned about this aspect of the assessment for quite a while.

As well as the external shape of each floor, we would have one notional extension in the central part of the property where a full 2-storey height ceiling was present, and one side of this building part followed an interesting curve of the main staircase.

I asked my DEA accreditation scheme whether they would accept floorplans with geometric calculations provided by the original architect. The repeated answer, despite several requests for clarification, was no, I would have to take manual measurements onsite.

Knowing this would be completely impractical, I approached the scheme manager at another company - Billy at Quidos. They were happy to accept such information as long as an assessor could satisfy themselves the property had not changed since the plans were drawn and that the plans were representative of the property.

For this and a couple of other reasons, I moved accreditation schemes.

Interested whether there may be an easier way of arriving at the figures, I posted on the members forum at Proficiency Services, and quickly recieved valuable information about taking the required measurements myself using the architect's floorplans directly.

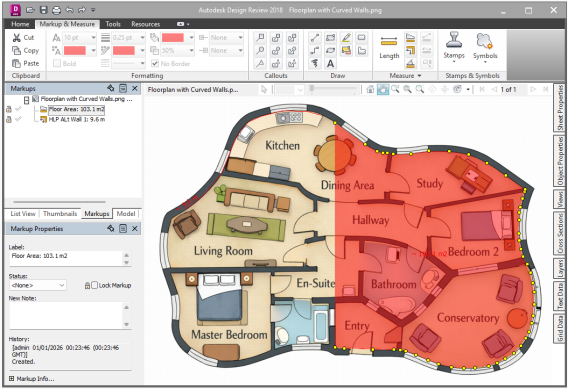

The answer was to use the free Adobe Design Review 2018 software, import a .pdf copy of the architect's floorplans and annotate using the 'polygon' tool to measure floor areas and the 'polyline' tool for wall lengths.

These would directly provide the measurements I needed, so long as I set the scaling factor in the software correctly, and this would be quite acceptable even when the EPC was audited.

For any energy assessors reading this, the scaling factor can be set by:

- Start by opening the plan and going to the "Markup & Measure" tab

- Use the "Length" measure to measure something you know the length of

- Divide the actual length by the length measured on the plan to get the scale factor

- Click the "Measure" dropdown and select "2D Units and Scale"

- Make sure you have 'metres' selected, then open the "Scale" dropdown, scroll to the bottom and select "Custom Scale"

- Leave the "On page" at 1 and enter your scale factor (from above) as the "Actual".

Here is an example floorplan produced by ChatGPT (NOT of the actual house), with these types of measurements being undertaken:

In the end it was a successful outcome when our measurements were accepted by the auditors.

Overriding U-Values

When buildings are initially constructed in England & Wales, an EPC is produced for building control requirements.

This has been the case since around 2008, and the methodology used at this stage is SAP, an acronym for Standard Assessment Procedure.

In fact one SAP EPC is produced during the design stages of a project and then a final one is produced and listed on the national register once the build is complete.

The SAP methodology calculates a rating using accurate thermal performance figures obtained from engineering information of materials in the construction of the property, and that information is easy to obtain at this stage in a building’s life.

Ten years later when the SAP EPC expires, owners may then need a new EPC to be produced, and because it is now an ‘existing dwelling’, a slightly different assessment methodology is used instead: RDSAP (Reduced Dataset Standard Assessment Procedure).

This uses the same underlying calculation engine as the SAP methodology, creating a model of the building and simulating it over the period of a year, but there are some differences in the information it needs to do so.

The main difference is that a smaller subset of information is needed to get a rating calculated, and additional assumptions are normally made by default in various areas, particularly around building fabric (walls, floors, roofs, windows etc.).

These assumptions are useful for existing dwellings because it is very unusual for owners to have accurate thermal performance information available about their properties.

Such information could be obtained retrospectively for existing dwellings by invasivley inspecting all parts of a building fabric. A suitably qualified person could then examine the materials and calculate thermal performance values of each element. They would produce a u-value certificate for each element, and the damage from the invasive inspection would need to be repaired.

Such work however would be very expensive and in the vast majority of cases the end result would normally only confirm either:

- The thermal performance of the building matches the minimum required by building regulations at the time of construction (1966 onwards in E&W for example), or

- The thermal performance of the building matches that of typical construction techniques at the time (pre 1966 in E&W for example).

For those that are interested, the RDSAP 10 Specification document hosted on the Building Research Establishment (BRE) website contains information about how the u-values (which represent the thermal performance of reach element) are either selected or calculated for walls, floors, windows etc. for existing dwellings.

The current version of this document is on the SAP 10 page here:

https://bregroup.com/expertise/energy/sap/sap10

Scroll down and click on the RDSP 10 Specification Document in the Downloads section.

So these u-values provide a numerical way of representing how fast energy is lost through a material and these are specified in Watts per metre squared Kelvin (W/m2K).

Kelvin has the same size units as degrees Centigrade and this represents the temperature difference from one side of the material to the other.

To calculate heat loss in a particular moment, the u-value is multiplied by the temperature difference and then multiplied by the area of the element to give the number of Watts being lost through that element.

Back to our subject though, and in summary, for the majority of properties where RDSAP is used, the assumed u-values result in a reasonably accurate assessment at a very reasonable cost to the property owner.

However, there are cases where buildings are constructed with energy performance that is significantly better than the minimum required by building regulations at the time.

Our 'Passivhaus' here is such an example, and there is the likelihood that without paying attention, an RDSAP EPC could be produced which doesn’t accurately reflect the thermal performance of the property - by this, I mean the rating would not be as good as it could/should be.

The methodology however provides the ability for an assessor to override these u-values.

This comes with some caveats however.

Firstly, documentary evidence is required to backup the overriding of these U-values and there are fairly stringent requirements for this.

Documents need to be linked to the property address somehow, u-value calculations need to show the name and qualifications of the person providing the calculations etc. Invoices or specification documents such as glazing etc. would also need to be linked to the property.

Secondly, the overriding of any building u-value, apart from those for windows and doors, will result in a SmartAudit trigger on any resulting EPC

This is described in the DEA Smart Auditing Rules, applied by the Energy Assessor Scheme Operating Board - http://easob.co.uk/

This means it is very likely the energy assessor will have their EPC audited by their accreditation scheme and the evidence scrutinised to make sure there is sufficient proof to support the overridden u-values.

If an EPC assessment fails audit, there are consequences for the assessor.

Energy assessors are therefore very careful to make sure that any evidence they submit is sufficient before overriding u-values in the assessment.

In the case of our 'Passivhaus', the owner had a huge quantity of documentary evidence, and had the ability to contact suppliers and the original architect to get further evidence if we we needed it.

In my limited experience in this field of work, this situation is extremely rare.

For this property we were able to override the u-values for:

- Floors (0.08)

- Walls (0.14 and 0.16 instead of 0.28)

- Roofs (0.10 instead of 0.18)

- Glazing (typically 0.96 to 1.4 instead of 2.2)

- Doors (0.82 instead of 1.8)

These are all components of 'building fabric' through which heat is lost to the outside.

When less heat is lost through the building fabric, the heating system has to work less to maintain the internal temperature of the property. This results in lower running costs, and because the EPC rating currently is a cost-based metric, the EPC rating is improved.

By making sure we entered the real-life u-values for this property into the assessment, the methodology calculated a more accurate and higher rating than it would have done otherwise.

The Products Characteristics Database (PCDB)

Another important area I wanted to check before visiting site was whether the main heating system and mechanical ventilation systems were listed in the Product Characteristics Database (PCDB).

During an EPC assessment, references are made to this database to import detailed information about any of the following items, if you have them in your property:

- Gas/Oil Boiler

- Heat Pump

- Compensating Heating Controls

- High Heat Retention Storage Heaters (HHRSHs)

- Mechanical Ventilation Systems (dMEV, MVHR etc.)

- Waste Water Heat Recovery Systems (WWHRS)

- Flue Gas Heat Recovery Systems (FGHRS)

This Database is separate from the EPC calculation 'software', and its managed by the Building Research Establishment (BRE).

Device manufacturers submit applications to the BRE to get their devices initially listed in the PCDB, and also to get entries for their devices modified.

There is a defined process for doing this and defined test procedures are in place for the different types of devices.

You can search for products within the PCDB yourself online here:

https://www.ncm-pcdb.org.uk/sap/

There are different sections for different types of devices, and you can search the database, using various criteria.

In our case we wanted to make sure the gas boiler and mechanical ventilation system were present in the PCDB so that accurate efficiency information would be brought into the EPC assessment, leading to the best EPC rating.

If these devices are not listed in the PCDB the assessor has to select the option for a generic gas boiler or a generic MVHR system for example, and this uses poorer efficiency values which result in a lower EPC rating.

Once we had located the devices and made enquiries as neccesary, we were happy to proceed.

Air Pressure Testing

Air pressure testing is the method of measuring how much air escapes unintentionally from a building through unsealed gaps, cracks and openings etc.

It excludes any air leakage through controlled systems such as extract fans.

This is relevant to EPCs and the energy performance of buildings because this air leakage affects the level of energy usage in a property.

In the Winter for example, warm air exiting a building through this type of leakage is replaced by cold fresh air from outside, and the heating system has to work harder to maintain the overall desired internal temperature.

This additional heating demand results in an increased use of 'fuel', and therefore cost - and EPC ratings are currently a cost based metric.

Usefully, just before the owner of the property approached me, on 15th June 2025 the assessment methodology for existing dwellings was updated to RDSAP 10.

Under this new version of the methodology it is now possible to record the results of an air pressure test into an EPC assessment.

Prior to this date, this information could not be included in an assessment of an 'existing dwelling', and was only recordable for new-build properties.

There has been some discussion in energy assessor forums about the acceptable age of an air tightness test certificate for use in an assessment, and despite there being no convention about this and information from our trade body advising that it does not matter, some forum postings indicated accreditation schemes implementing age limits.

Partly with this in mind, the property owner commissioned a new air tightness test, and we were able to input this into the assessment to help achieve the best rating.

This turned out to be advantageous because the old test result appeared to have been an amalgamation of the property along with it's annexe, which had a much lower level of air tightness.

The new test result was therefore better than expected, and assisted in getting the best EPC rating.

The Outcome

We submitted the EPC with Quidos and 6 weeks later it was flagged for audit as expected by two SmartAudit triggers:

- Rule 32: Overiding of the u-values for any building element (apart from windows & doors)

- Rule 22: Ceiling height in any floor (ie storey) of any building part, room height is <1.5m or >4m

We uploaded our 500MB of evidence and a successful audit result was received quickly just under two weeks later.

We achieved an EPC rating of 105A which was a great outcome.

A rating of 100A would mean the property had been modelled to be cost-neutral in terms of energy use - energy bills therefore being zero.

105A means the property is slightly better than that, and effectively makes a financial return over a full year, due to the solar systems present.

The previous rating was a combined assessment of this property and an annexe built mostly to standard building regulation requirements, therefore weighting that rating down.

We therefore could not compare directly with a previous rating, however it was pleasantly better than the combined rating.