Passivhaus RDSAP EPC - A105

An Interesting Challenge

In the middle of 2025 I was approached by a client to carry out an RDSAP EPC assessment of a 10 year old property built almost entirely to Passivhaus standards.

At the time of construction in 2015, a SAP EPC was conducted to fulfill Building Control requirements, and with a lifespan of 10 years that EPC was just about to expire.

The property owner was looking to market the property and would therefore require a new EPC to do so legally, and he was looking to get the best outcome.

This was a significant property with much bettter thermal performance than the minimums required by building control and significanylt, only minimal lengths of external wall were straight.

The owner however had been heavily involved in the initial construction of the property and continued to maintain successful relationships with all parties involved, so the documentary evideince available was extensive.

To provide the best outcome in terms of accurate assessment and EPC rating for this property it was quickly clear that some areas needed considering before visiting site. These were:

- The significant size and scale of the property.

- How to measure basic geometry of a property where only minimal lengths of external wall were straight.

- Overiding u-values to get the most accurate EPC rating and provide justice to the building.

- Checking installed systems to make sure they were available in the PCDB such as heating and ventilation.

I was interested, but I was quite worried about being able to provide the best outcome.

Despite this the owner convinced me it would be possible somehow and would work out fine.

Basic Geometric Measurements

There are some basic geometric measurements of a property that energy assessors take when conducing an EPC assessment.

These apply to each floor of the building plus any ‘extensions’ which may be real extensions, or virtual ones - where a property is split into different parts having differing ceiling heights or floor types or roof types etc.

In particulare the measurements calculated include:

- Floor area

- Lengths of external wall (known as the Heat Loss Perimeter)

- Lengths of any party wall

For a ‘standard’ rectangular house this is straightforward and an assessor simply uses a laser measure to take readings of the length and width of the property and multiplies the two numbers together to arrive at the floor area.

Also, measuring lengths of external wall is straightforward meaning that multiple lengths of party wall of multiple lengths of HLP wall can be easily summed to create the results.

In the case of our Passivhaus property however, we had a challenge because none of the walls were straight. It was clear at the start that a different solution would be required to make these basic measurements, and I didn't have a solution for this at the time.

As well as the external shape of each floor, we would have one extension in the central part of the property where there was a full 2-storey height ceiling and the delineating area of this part followed an interesting curve of the main staircase.

I posted on the Forum at Proficiency Services, and recieved good information very quickly about how to take these measurements.

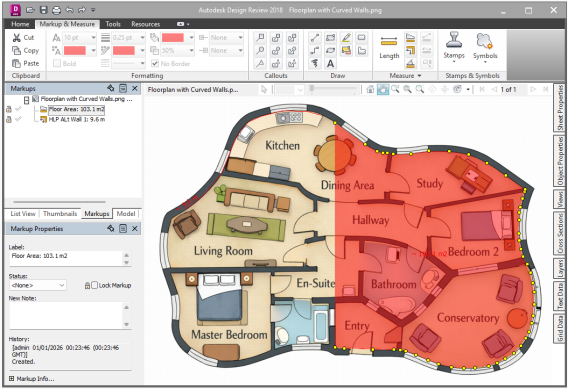

We can demonstrate this using an example floorplan that ChatGPT created for me of a two-bed bungalow with curved walls.

The solution was to use Adobe Design Review 2018, import a .pdf copy of the floorplans for the building and then annotate the floorplans using a polygon tool for the floor area and the polyline tool for wall lenghts. Here is our example floorplan with these types of measurements being undertaken:

The only thing we need to do is

Overiding U-Values

When buildings are initially constructed, an EPC needs to be produded for building control requirements. This has been the case since around 2008, and the methodology used for this is SAP, an acronym for Standard Assessment Procedure.

In fact one SAP EPC is produced during the design stages of a project and then a final one is produced and listed on the national register one the build is complete.

The SAP methodology calculates a rating using accurate thermal performance figures obtained from engineering information of materials in the construction of the property, and that information is easy to obtain at this stage in a building’s life.

Ten years later when the SAP EPC expires, owners may then need a new EPC to be produced, and because it is now an ‘existing dwelling’, a slightly different assessment methodology is used instead: RDSAP (Reduced Dataset Standard Assessment Procedure).

This uses the same underlying calculation engine as the SAP methodology, creating a model of the building and simulating it over the period of a year, but there are some differences in the information it needs to do so.

The main difference is that a smaller subset of information is needed to get a rating calculated, and additional assumptions are normally made by default in various areas, particularly around building fabric (walls, floors, roofs, windows etc.).

These assumptions are useful for existing dwellings because it is very unusual for owners to have accurate thermal performance information available about their properties which would otherwise be required.

Such information could be obtained retrospectively for existing dwellings by intrusively inspecting all parts of a building fabric. A suitable qualified person could then examine the materials and calculate thermal performance values of each element. They would produce a certificate for each element, and the damage from the invasive inspection would need to be repaired. Such work however would be very expensive and in the vast majority of cases the end result would normally only confirm either:

- The thermal performance of the building matches the minimum required by building control at the time of construction (1966 onwards in E&W for example), or

- The thermal performance of the building matches that of typical construction techniques at the time (pre 1966 in E&W for example).

For those that are interested, the RDSAP 10 Specification document hosted on the Building Research Establishment (BRE) website contains information about how the u-values (which represent the thermal performance of reach element) are either selected or calculated for walls, floors, windows etc. for exisrting dwellings.

The current version of this document is on the SAP 10 page here:

https://bregroup.com/expertise/energy/sap/sap10

Scroll down and click on the RDSP 10 Specification Document in the Downloads section.

So these u-values provide a numerical way of representing how fast energy is lost through a material and these are specified in Watts per metre squared Kelvin (W/m2K).

Kelvin has the same size units as degrees Centigrade and this represents the temperature difference from one side of the material to the other.

In practice, the u-value is multiplied by the temperature difference and then multiplied by the area of the element to give the number of Watts being lost through that element.

Back to the subject though, in summary, for the majority of properties where RDSAP is used, the assumed u-values result in a very reasonable assessment at a very reasonable cost to the property owner.

However, in other cases where buildings are constructed with energy performance that is significantly better than the minimum required by building regulations at the time, such as this Passivhaus, there is the likelihood that without paying attention, RDSAP EPCs could be produced which don’t accurately reflect the thermal performance of the property. By this, I mean the rating would not be as good as it could/should be.

For these cases, the methodology makes available the ability to override the u-values with those provided by the energy assessor.

This comes with some caveats however.

Firstly, documentary evidence is required to backup the overriding of these U-values and there are fairly stringent requirements for this. Documents need to be linked to the property address somehow, u-value calculations need to show the name and qualifications of the qualified person providing the calculations etc. Invoices or specification documents such as glazing sizes etc. would also need to be linked to the property.

Secondly, the overriding of any building u-value, apart from those for windows and doors, will certainly result in a SmartAudit trigger on any resulting EPC.

This is described in the DEA Smart Auditing Rules, applied by the Energy Assessor Scheme Operating Board - http://easob.co.uk/

This means it is very likely the energy assessor will have their EPC audited by their accreditation scheme and the evidence scrutinised to make sure there is sufficient proof to support the overridden u-values. Energy Assessors will therefore be very careful to make sure that any evidence is sufficient before overriding u-values in the assessment.

In the case of our Passivhaus, the owner had a huge quantity of documentary evidence, and this is extremely rare.

We were able to override the u-value for:

- Floors

- Walls

- Roofs

- Glazing

- Doors

These are all components of building fabric where heat is lost to the outside world, particularly during the winter.

The main heating system needs to produce heat to replace this lost heat, and maintain the inside temperature.